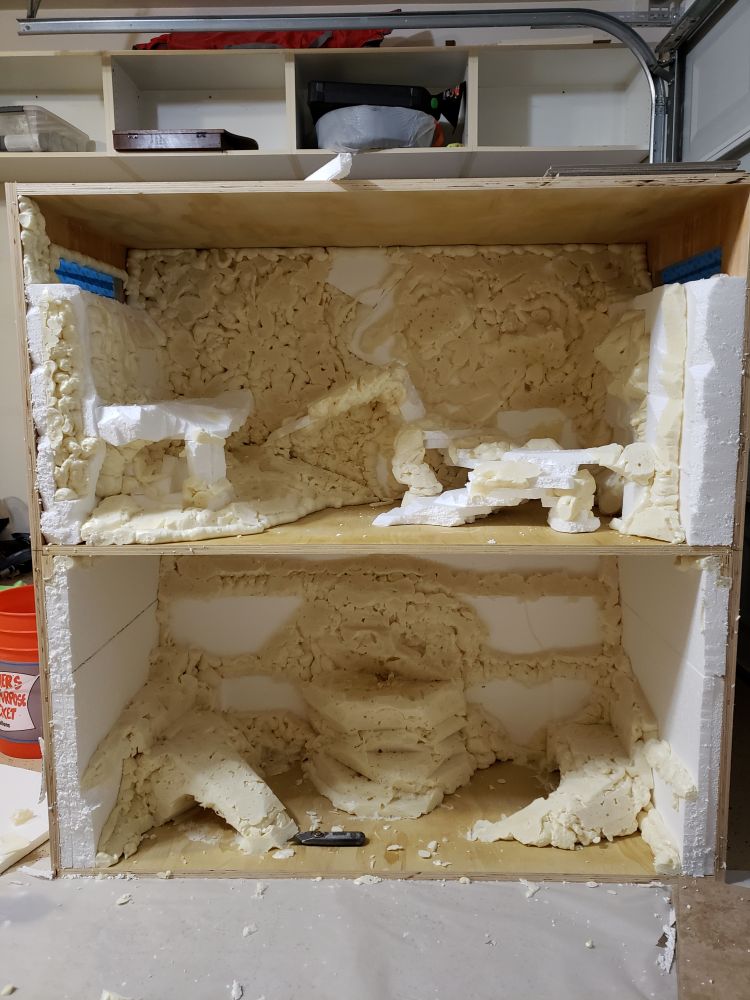

The goal with this project was to make a furniture grade double stacked 4x2x2 (4x2x4) for my dragons. I plan on going all out with a custom DIY rock feature in both of them which will add a lot of life to the tanks I believe.

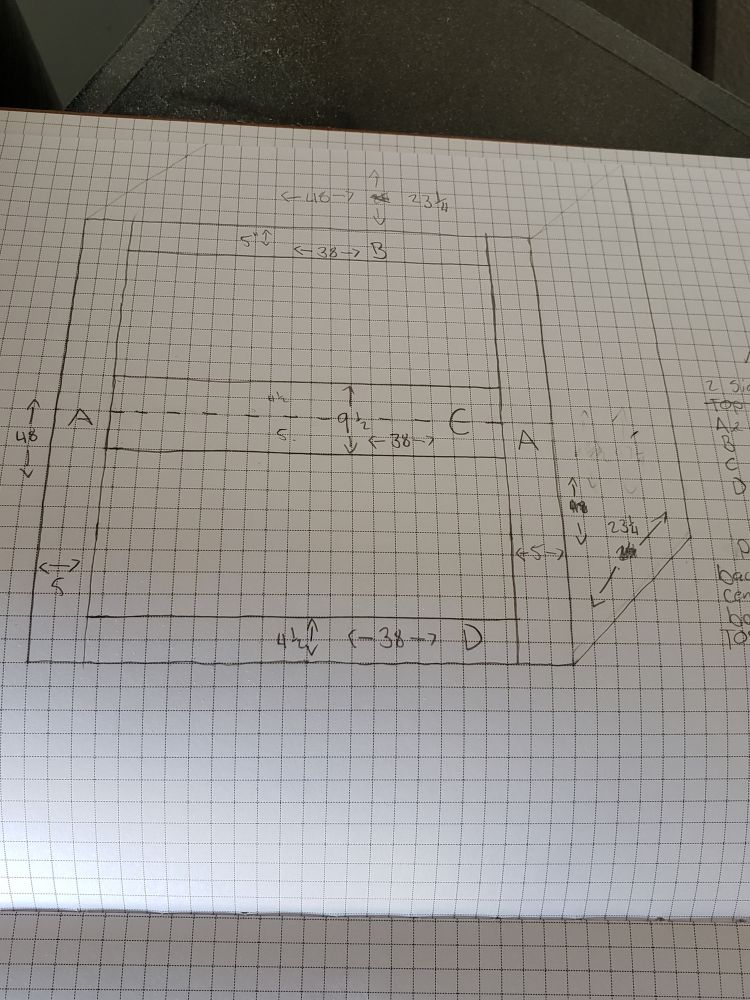

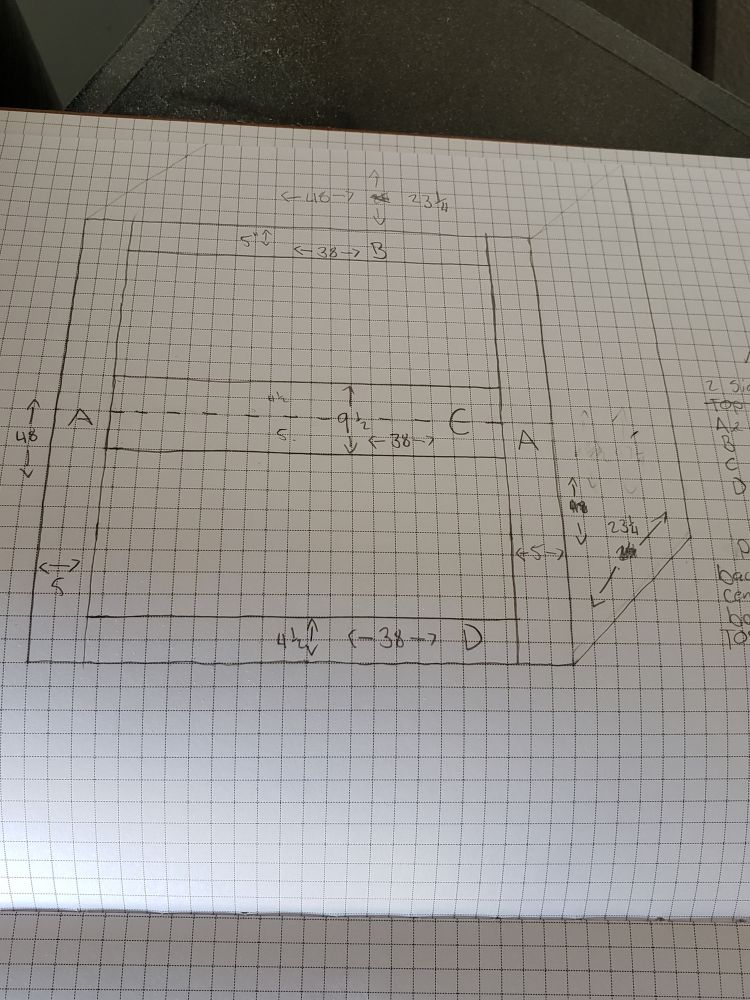

I started out with drawing it out so I could get dimensions right and a general idea of what it would look like (trust me this step helps a lot)

From their I could measure out each piece on paper and plug them into a cutlist optimizer. I highly suggest using a program or an app to do this. It will tell you the most efficient way to make your cuts especially if you are using ply. It will arrange the pieces so that as many pieces as possible fit onto a sheet and you waste as little as possible.

For me, I used 1 sheet of Maple ply, and 2 sheets of smooth sanded pine ply. The maple being more expensive, it made sense to only use it for the outside portions of the build, the parts that would be seen. The pine will fill in the rest because most of it will be covered or not visible.

Anyways, all the pieces were cut BEFORE starting assembly. I suggest this also just because IMO it makes everything easier, quicker and smoother. You just HAVE to make sure you've gone over all your measurements in your head first and verified that everything is going to go together how you expected it to.

Once you are sure, cut.

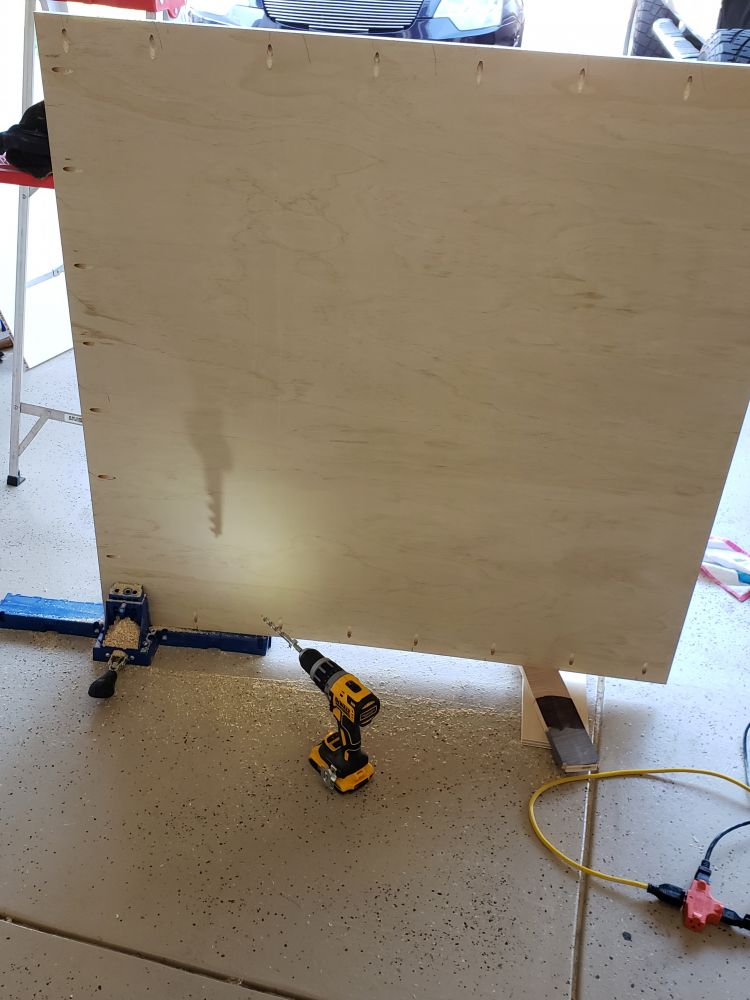

Here is my maple pieces cut

We have the two sides, and the few pieces that will make up the front of the build. I didn't make the top out of maple simply because the build is already going to be 4 feet tall; I plan to build a 3 foot tall stand too, so the whole piece is going to be 7 feet high. I don't think anyone will be seeing the top :mrgreen:

We have the two sides, and the few pieces that will make up the front of the build. I didn't make the top out of maple simply because the build is already going to be 4 feet tall; I plan to build a 3 foot tall stand too, so the whole piece is going to be 7 feet high. I don't think anyone will be seeing the top :mrgreen:

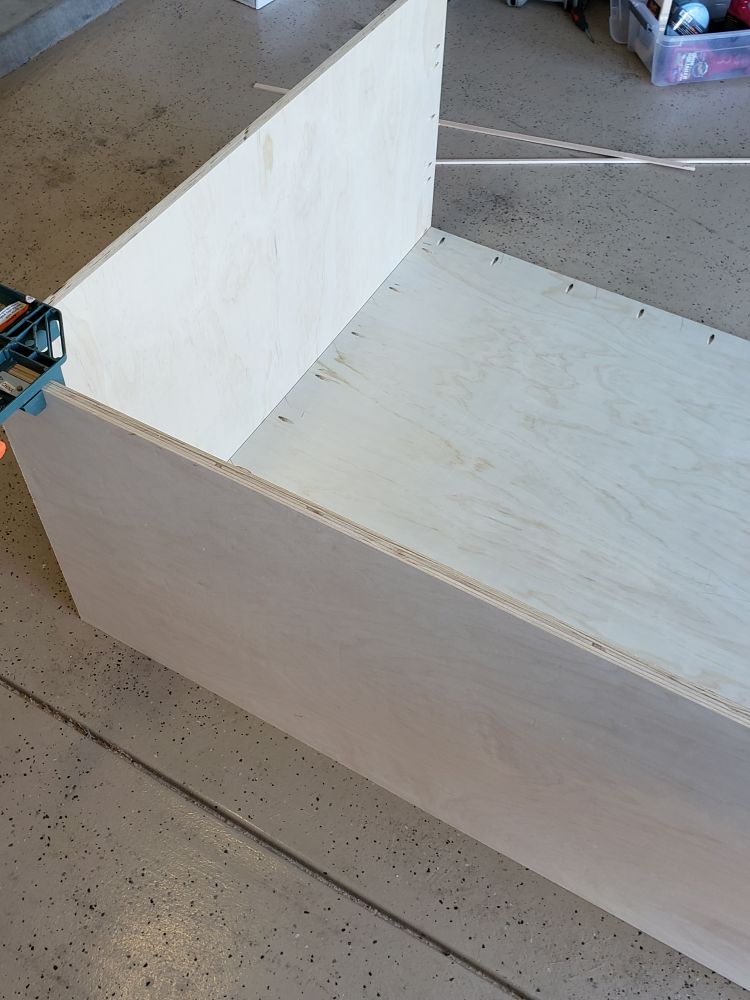

Pine pieces cut

There are 3 pieces there but they are basically the same sizes.

There are 3 pieces there but they are basically the same sizes.

-Brandon

I started out with drawing it out so I could get dimensions right and a general idea of what it would look like (trust me this step helps a lot)

From their I could measure out each piece on paper and plug them into a cutlist optimizer. I highly suggest using a program or an app to do this. It will tell you the most efficient way to make your cuts especially if you are using ply. It will arrange the pieces so that as many pieces as possible fit onto a sheet and you waste as little as possible.

For me, I used 1 sheet of Maple ply, and 2 sheets of smooth sanded pine ply. The maple being more expensive, it made sense to only use it for the outside portions of the build, the parts that would be seen. The pine will fill in the rest because most of it will be covered or not visible.

Anyways, all the pieces were cut BEFORE starting assembly. I suggest this also just because IMO it makes everything easier, quicker and smoother. You just HAVE to make sure you've gone over all your measurements in your head first and verified that everything is going to go together how you expected it to.

Once you are sure, cut.

Here is my maple pieces cut

Pine pieces cut

-Brandon